AMDI Design Process

AMDI’s design process is a comprehensive and collaborative approach focused on transforming client ideas into effective, innovative products. By combining thorough research, iterative prototyping, and advanced engineering analysis, AMDI ensures that each design meets the client’s specific needs, performance goals, and industry standards. This structured process promotes efficiency, creativity, and precision at every stage of product development.

1

Initial concept and ideation

At AMDI, client product ideas undergo a structured, multi-step innovation process designed to ensure the most effective and efficient product outcomes. This process may include a stakeholder questionnaire, patent research, whiteboard concept iteration, design ranking, and initial feasibility designs. By following this comprehensive approach, AMDI consistently delivers solutions that align with client needs and goals. All ideation and development activities are thoroughly documented and shared with the client to support patent applications or guide the next steps in product development.

2

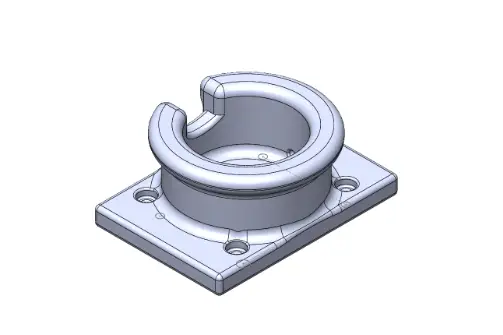

Solid modeling

Once a few designs are selected, solid modeling is used to further refine and develop the concepts with precise engineering dimensioning and tolerancing. These solid models serve multiple purposes, including proof of concept, 3D printing, the creation of detailed design specifications, communication with suppliers, and advanced simulations such as Finite Element Analysis (FEA) or Computational Fluid Dynamics (CFD) analysis.

3

Iterative 3D printing

Following solid modeling, an iterative 3D printing process is conducted to determine the optimal part fit, function, tolerances, and printing method. At AMDI, a variety of 3D printing technologies are available to meet functional requirements, including Liquid Photopolymer 3D Printing, Polymer Melt Extrusion, and Metal Melt Extrusion. These diverse additive manufacturing methods offer broad flexibility in material properties, dimensional tolerances, and resolution, enabling the development of optimized 3D printed solutions tailored to each specific application.

4

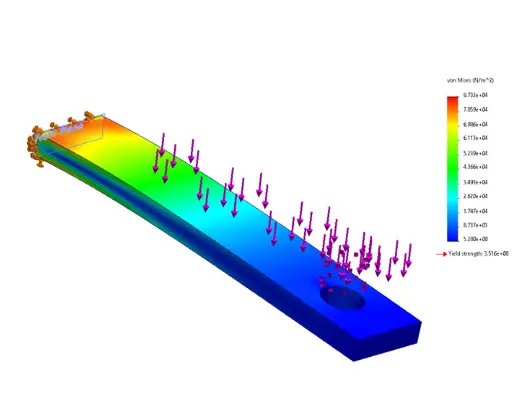

Part analysis: finite element analysis

For further analysis or to meet safety specifications, Finite Element Analysis (FEA) can be performed on parts to gain critical insights into their performance. FEA enables the identification of failure points, areas of high stress, potential deformation, and strain within the part. This advanced analysis provides a deeper understanding of how a part will behave under real-world conditions and supports the optimization of design features to enhance performance, reliability, and safety.

5

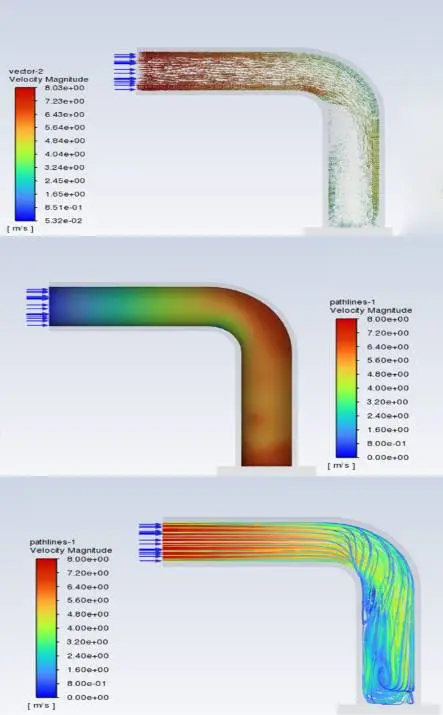

Part analysis: computational fluid dynamics

When working with fluidic systems, Computational Fluid Dynamics (CFD) is used to analyze and visualize how fluid flows through the design. CFD enables detailed evaluations that support part and fluid flow optimization, pressure distribution analysis, and the assessment of both fluid and wall shear stresses. This level of analysis helps refine system performance, improve efficiency, and ensure the design meets functional and safety requirements.

Want to learn more about our design process?